Works like chemistry

But without chemistry

What is Hybrid Herbicide?

And how does it work? What effects does volt.fuel have on the soil and crop quality? We have prepared these and many other aspects of our alternative to classic herbicides for you here.

The agronomic effects

The implications and issues related to the agriculture of the future are complex. We’ve compiled the most important questions and answers around the use and effects of hybrid herbicides.

How does

Hybrid Herbicide

technology work?

Immediately before electric application, the plants are pre-treated with the conductive liquid volt.fuel via a field sprayer on the front hydraulics of the tractor.

A PTO-driven generator is attached to the rear hydraulics of the tractor, which converts the mechanical power of the tractor into three-phase current. The electrical power is then distributed via an integrated control cabinet to the max. 16 high-voltage units that supply the applicators.The applicators are arranged on a hydraulically folding boom behind the volt.cube.

Electrode units with different polarity are located at the applicators. Touching the plants closes the circuit and cells, especially in the water conduction bundles, are destroyed immediately. Depending on the type of plant and the applicator, this initiates the ripening process, e.g. the skin firmness of the potatoes is promoted or the entire plants simply dry out. The drying of the plants takes several hours to several days, depending on the plant and weather conditions. In total, this system works with a power between 1600-5500 volts and with a maximum of 10 kW/75 cm. With a working width of 12 m and a working speed of up to 8 km/h, an area output of 4-5 ha/hour can be achieved.The machine weighs 2.4 tons and 145 kW (12 m system) of power is required at the PTO. We also offer equipment with a width of 9 m.

Proven effectiveness

crop.zone works. And it does so demonstrably and sustainably. The hybrid herbicide shows its advantages over conventional chemical herbicides in particular.

Industrial potatoes

Seed potatoes

Table potatoes

Round thing.

Excellent quality and harvest without additional waiting time with herbicide-free siccation with crop.zone.

Better planning of the

harvesting work due to fewer operations

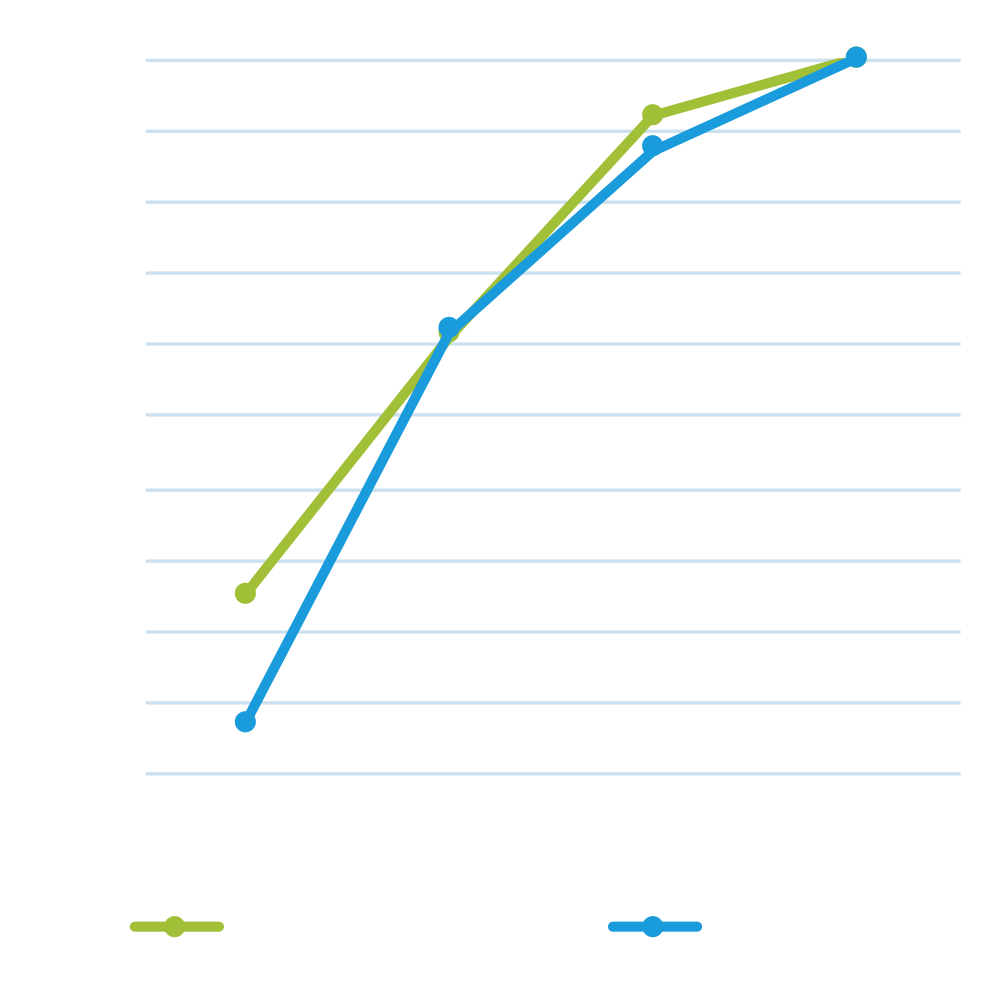

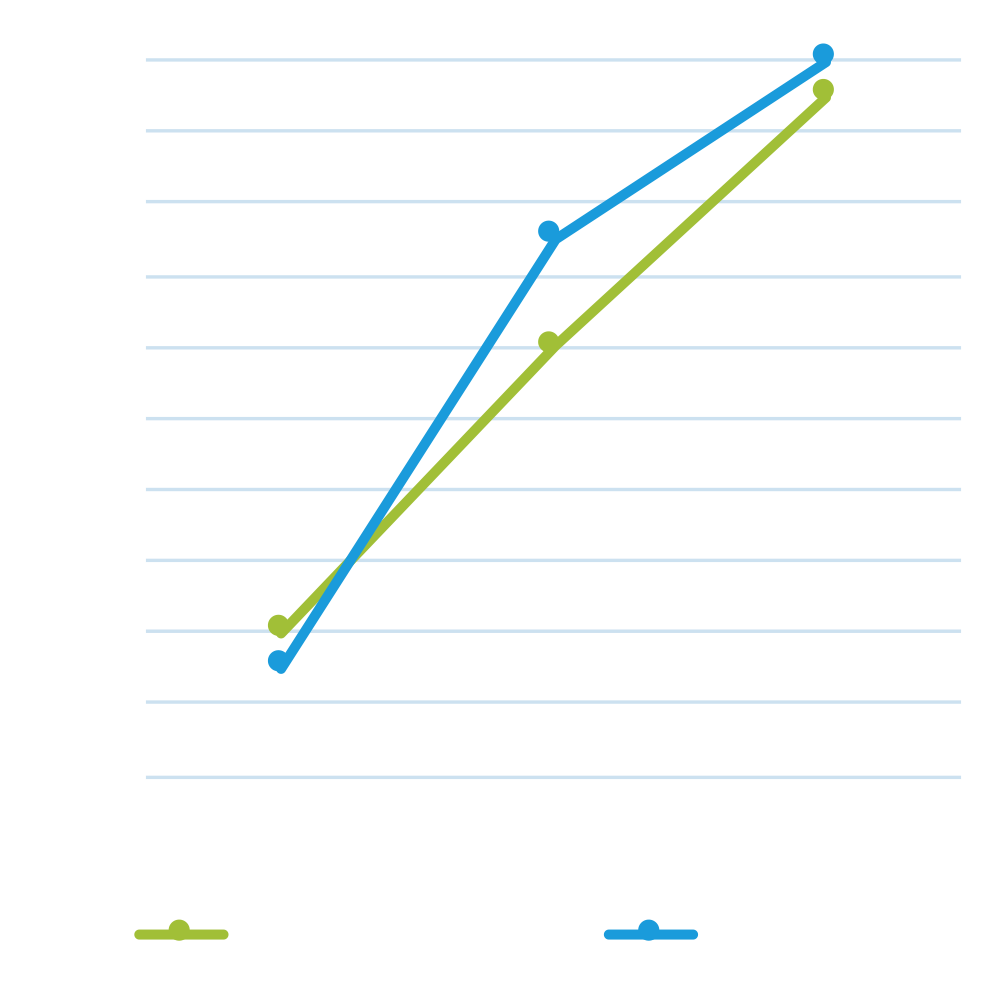

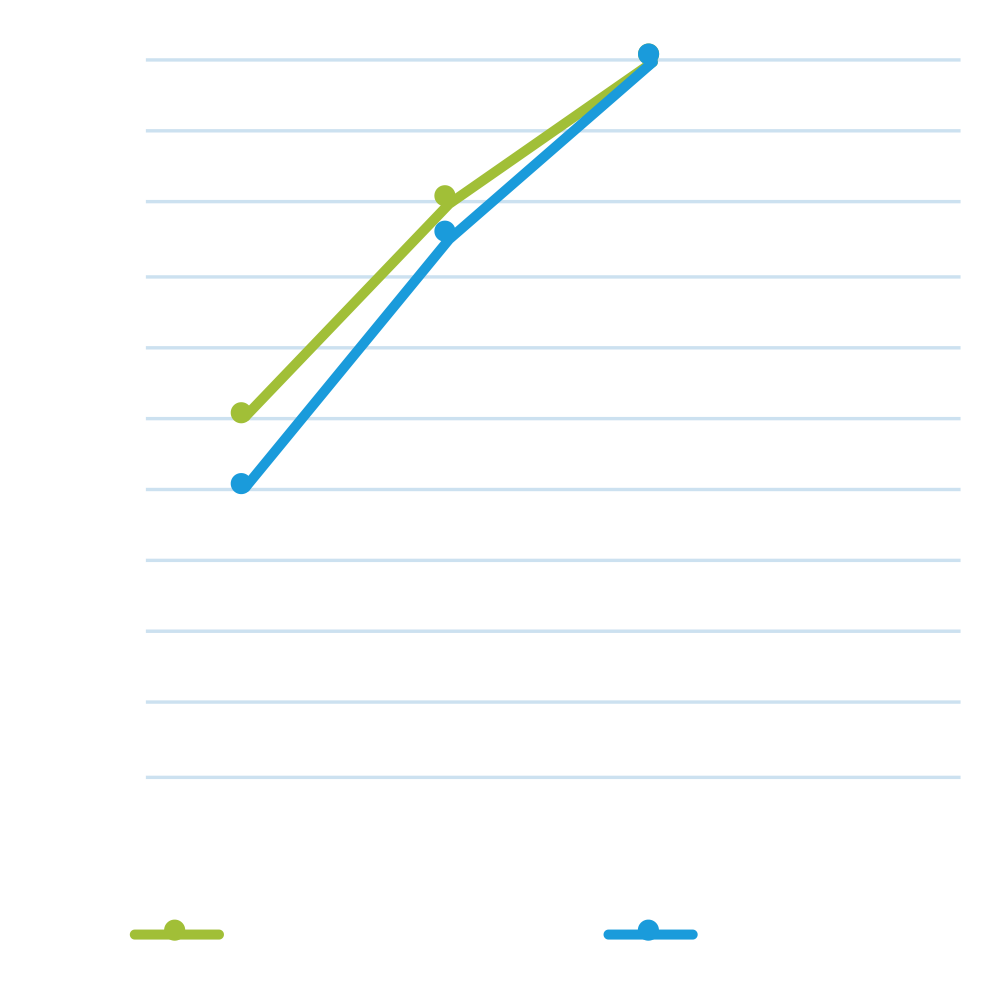

With Hybrid Herbicide technology

In many cases, a single Hybrid Herbicide treatment is sufficient. This is because one Hybrid Herbicide treatment normally replaces two chemical treatments. And if two treatments are necessary, there are no statutory waiting periods. This makes it easier to plan the harvest.

With conventional chemical methods

In many cases, more than two chemical treatments are needed and even three treatments are often barely sufficient with the chemical herbicides still available. . Then there are the statutory waiting periods, which make it difficult to plan the harvest.

Convincing results – after just a few days

The following pictures show the development after a single application.

Day 1

The first effects of the treatment are visible after a few hours.

Day 3

After three days, almost the entire siccation is completed.

Day 6

A perfect result in less than a week and after only one application.

Any questions?

Feel free to call us or contact us via the contact form.

We will be happy to answer your questions personally.